It seems like every other day we read about some far-out, new technology that makes us scratch our heads and say, “What the heck?” In this series, we’ll take a look at all types of crazy new gadgets, apps and other technologies — and the entrepreneurs dreaming them up.

If Vincent Van Gogh were alive today, doctors could have replaced his ear like new, thanks to recent mind-blowing breakthroughs in 3-D bio-printing.

The world’s first 3-D printer debuted back in 1983. In the three decades since, 3-D printers have churned out everything from holiday ornaments to electric cars to chocolate bars and beyond.

But perhaps their most important contributions so far are the kind humans can benefit from the most — living replacementbody parts manufactured on-demand from a blend of real, live cells and synthetics.

Here’s an eye-opening roundup of body parts already being 3-D printed throughout the U.S.

1. Skin: Regenerative burn tech that’s more than skin deep.

What if real skin cells were printer jet “ink”? It sounds impossible, but they already are.

Scientists at the Wake Forest Institute for Regenerative Medicine in Winston-Salem, North Carolina, have custom built a 3-D bio-printer that actually prints human skin cells directly on burn wounds.

First, the machine uses a scanner to scan, assess and map the patient’s burn wound size and depth. Next, data “guides the printer as it applies layers of the correct type of cells to cover the wound,” according to the researchers.

To create skin, one of the printer’s inkjet valves emits the enzyme thrombin while another emits cells blended with fibrinogen, the body’s principal protein in blood clotting, as well as collagen, the body’s main structural connective tissue protein. After the printer applies these, it finishes the process by printing a layer of human fibroblasts and, finally, a layer of skin cells known as keratinocytes.

A smaller, portable version of the skin printer is in the works for use in war- and natural disaster-torn areas.

2. Ears: Rat tails and cow parts — the stuff that 3-D printed ears are made of.

Bioengineers and doctors at Cornell University’s Weill Cornell Medical College have 3-D printed an artificial ear that looks and feels real using a freaky mix of ingredients from some interesting sources, including rat tail bone collagen and cow ear cartilage.

The soft, flexible bioengineered ear, which its makers say is “practically identical to a human ear,” gives hope to thousands of children born each year with microtia, a congenital ear deformity. People who have lost part of their external ear from cancer or from an accident could also benefit from the replacement ear.

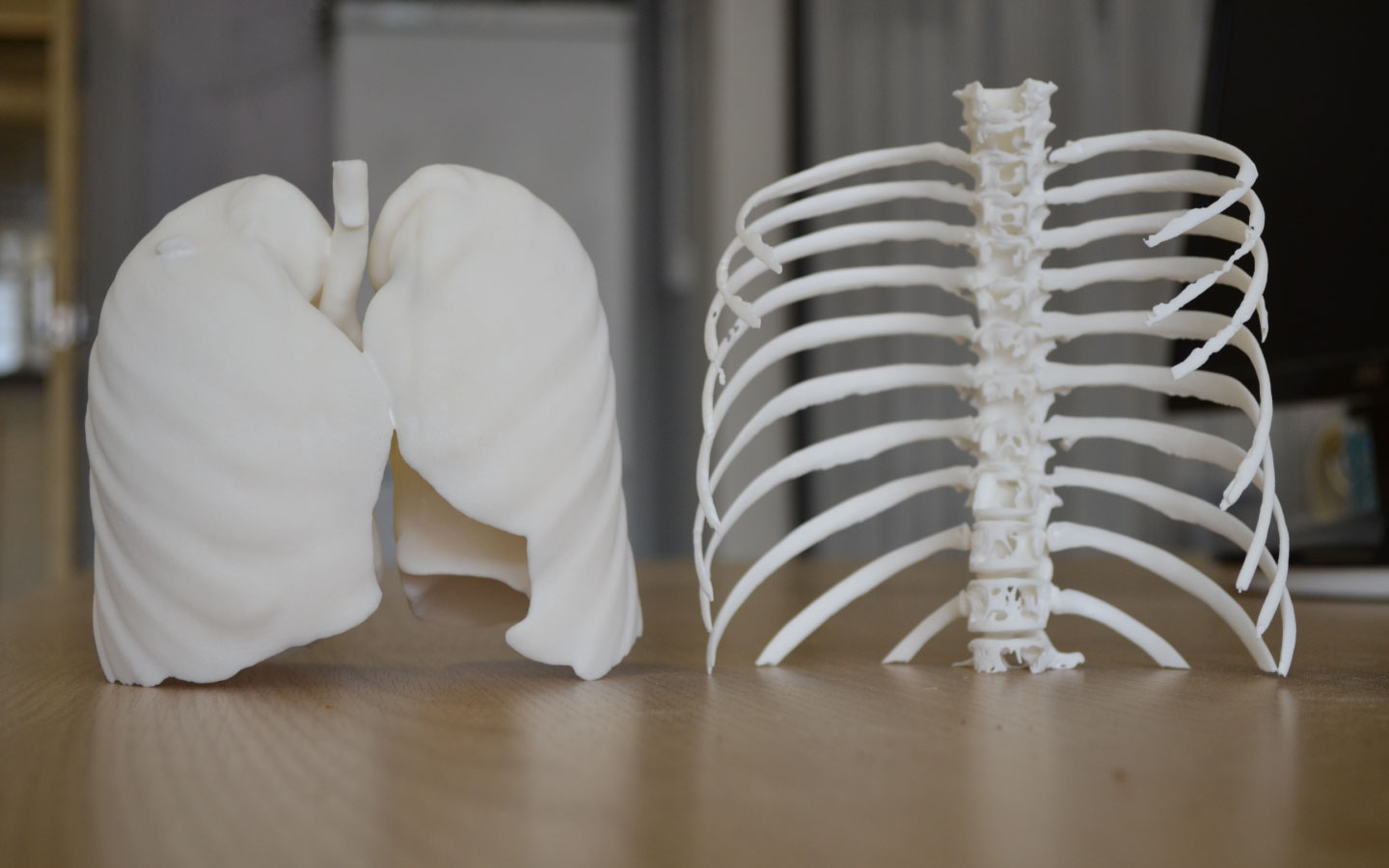

3. Bones: 3-D bio-printers can help mend them.

Yes, an inkjet printer can pump out bones that look, feel, and act real. Researchers at Washington State University used a 3-D bio-printer to print out a bone-like material that could one day help treat dental problems, complex bone fractures and bone disorders like osteoporosis.

The printed substance, which was successfully tested on rabbits and rats, serves as a support scaffolding for new human bone cells to form on. It conveniently dissolves once bone regeneration is complete. Doctors might eventually use this technology to print bone grafts on demand right from their exam rooms.

Pretty cool, right?